Engineering

Revolutionizing the future of plastic engineering

Plastic Injection Molding

Shaping the future of plastics manufacturing with precision, and innovation driving the next era of production.

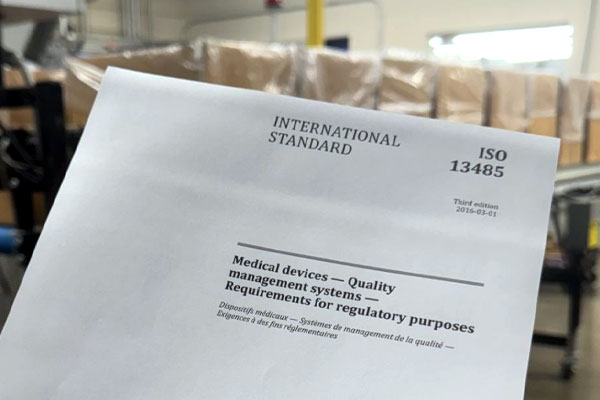

Achieving ISO Readiness

ISO 13485 & ISO 9001 ensures that all medical devices meet the proper regulatory compliance laws and customer needs.

Scientific Injection Molding

Improving process efficiency using 6-Step scientific injection molding with FimmTech tools and DoE software.

Precision Engineering

Precision plastics engineering is the key to creating flawless plastic manufacturing products with unmatched accuracy and durability.

Strategic Processes

Engineering is fundamentally a science, driven by data, principles, and proven methodologies to achieve precise and reliable injection molding results.

Outstanding Engineered Parts

This scientific engineering approach ensures that every design, calculation, and process is optimized for efficiency and performance, leading to tangible, high-quality outcomes.

Markets

Medical & Pharmaceutical Plastics

We leverage advanced materials and cutting-edge injection molding and microfabrication, to produce durable and reliable parts tailored to client needs.

Custom Plastic Engineered Parts

Utilizing state-of-the-art equipment and expertise to create precise plastic parts with exceptional accuracy and consistency.

About

Plastics Engineers of Tomorrow

Every employee contributes their unique skills and commitment to the shared goal. KMOL Plastics Engineering makes products that exceed expectations and make a lasting impact. Together, the team transforms raw materials into precision-crafted solutions, proving that great results are achieved through unity and collaboration.

Principals

Philosophy for Pioneering Plastics

1. Precision

Precision fosters quality

2. Quality

Quality builds trust

3. Trust

Trust paves the way for growth

4. Growth

Growth leads to new opportunities

Provide us with a few details about your product.